Control of Cronobacter in Dairy Dryer and Packaging Rooms

By Beth Koenig, EAS Independent Consultant

What Is Cronobacter and Why Should We Be Concerned About It?

Cronobacter, a genus of bacterial pathogens in the Enterobacteriacea family is of considerable concern in infant formula manufacturing and in the manufacture of products for populations with compromised immune systems. The genus includes seven species, the most familiar of which is C. sakazakii. Cronobacter is naturally found in the environment and is able to survive in low-moisture, dry foods such as powdered infant formula and dry milk. Illness caused by Cronobacter can be serious and even deadly to infants and people with compromised immune systems and it has been the cause of several large recalls in recent years. This microbe tends to flourish in habitats where moisture and food is abundant. Damp floors, pooling water, damaged grout, floor crevices and spilled product are particularly suitable for growth of the bacteria.

How Do We Control This Threat?

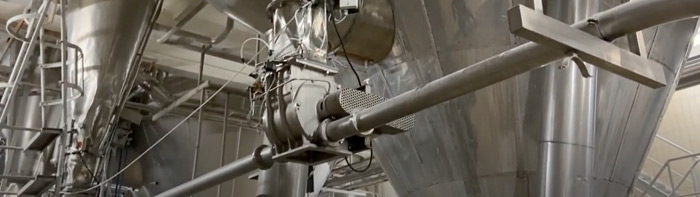

Control of Cronobacter is best accomplished by eliminating the conditions that promote growth in the environment. In dairy dryer and packaging rooms, keeping floors dry and clean is critical. Separation of wet from dry processes is an important consideration when designing the room to control not only Cronobacter, but other pathogens such as Salmonella and Listeria as well. In older facilities, retrofitting the dryer room for wet-dry separation is more challenging, but is achievable. This can be accomplished by diverting water discharge directly to drains, insulating cooling lines with smooth cleanable insulation, and, where insulation is not possible, installing collection pans to direct condensate to drains. Installation of curbing or walls where possible will isolate wet processes. Once rooms have been correctly designed or modified, appropriate cleaning methods are the next step in controlling the pathogen.

The goal is to keep dry areas as dry as possible, which is typically accomplished by routine dry cleaning and periodic controlled wet washes. Large quantities of product can be removed with shovels and dry squeegees. Brooms are not recommended as they can harbor bacteria on the bristles. Removal of light layers of powdered product can be performed with explosion proof HEPA filtered vacuums with designated attachments. Special consideration should be given to washable, separate vacuum attachments for each zone to prevent cross contamination and the program must include a stringent cleaning, drying and storage process for the parts. After vacuuming non product contact equipment, paper towels or alcohol wipes can be used to complete the cleaning and sanitizing process.

Controlled wet washes must be performed under tightly supervised conditions, which include: minimal water use, appropriate cleaning chemicals, squeegeeing the water to the drain immediately and sanitizing the area after cleaning. After a wet wash, additional environmental swabbing is necessary to verify that it did not encourage growth.

In addition to stringent cleaning programs, traffic control in high hygiene rooms is critical to preventing introduction of pathogens into the area. Limiting access to dryer and packaging rooms, eliminating wheeled traffic except for during downtimes, changing footwear and outwear upon entering critical areas and tool control all assist in maintaining a controlled environment for sensitive ingredient production.

EAS Consulting Group LLC can provide a comprehensive survey and mitigation strategy for the control of pathogens in your facility.

Posted in Foods, Issue of the Month.